Extracting oil from cannabis is growing by leaps and bounds across the world. If you are not purchasing or selling a flower, then the ingredients for the other products have most likely been concentrated from the plant. And, the art of extraction of the botanical active ingredients is eons old.

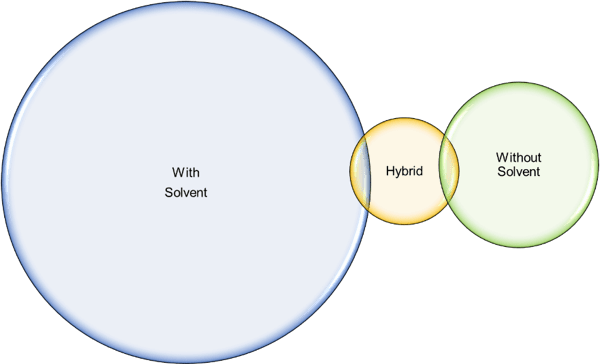

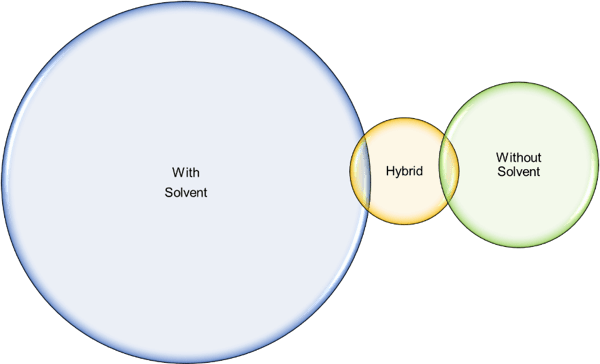

There are three choices for extraction of cannabis and hemp.

Solvent based and Solvent-less extraction are the obvious ones.

The fastest growing category – though currently the smallest – are the hyphenated extraction techniques and technologies.

Solvent based extraction includes the use of butane, propane, water, ethanol, carbon dioxide, fluorocarbons, and hexane which are some of the most popular choices.

The most commonly used non-solvent based techniques used in the extraction industry today include pressing, mechanical shaking, ultrasonic and microwave.

The third category is the hybrid/hyphenated products.

Figure 1: General Representation of the Installed base of Extraction Technologies

With hyphenated extraction, you are adapting the best of two processes.

The simplest example is the use of ethanol with current Supercritical CO2 (SCC). Interest in this technique has increased a result of the formal work out of Denver, CO in early 2017.[1]

Other hyphenated examples include the use of ultrasonic release of the cannabinoids and then the sweeping of them into collection flasks by SFE. Releasing the trichomes content by bursting the cell wall greatly increases the extraction rate of SCC.[2]

Another obvious hyphenated technology is the merging of the extraction with on-line separation technology. Additional techniques include counter current chromatography[3] as well as simulated bed chromatography[4]. Both provide more selectivity of components in the extraction mixtures.

The key question for operators still involves scaling manufacturing. At what point in time does a company decide to enter the extraction in their facilities versus purchasing from an outside vendor?

As usual the determining factor should be based on your businesses objectives. If you have a limited amount of cannabis available, then how much time is the instrument being utilized? What is the expert doing when not running the instrument?

If you have thousands of pounds of a single strain or are making a blend, then how do you extract all that product into oil? What are the choices you need to make based on the local regulations?

There are more and more companies providing all of these technologies It is worth the time to explore them before your next investment.

[1] Laura J. Rovettoa, Niccolo V. Aieta, Supercritical Carbon Dioxide Extraction of Cannabinoids from Cannabis sativa L., J. of Supercritical Fluids 129 (2017) 16–27

[2] “Optimisation and characterisation of marihuana extracts obtained by supercritical fluid extraction and focused ultrasound extraction and retention time locking GC-MS”, Jone Omar, Maitane Olivares, Mikel Alzaga, Nestor Etxebarria, J. Sep. Sci. 2013, 36, 1397–1404.

[3] https://en.wikipedia.org/wiki/Countercurrent_chromatography

[4] https://en.wikipedia.org/wiki/Simulated_moving_bed