By Jeremy Applen, Vice Chairman ASTM D37 and Leslie Engleking

With each passing year, FOCUS (Foundation of Cannabis Unified Standards) is asked to investigate more and more cases of theft and diversion throughout the cannabis industry. Findings from records audits and compliance checks continually reveal sophisticated diversion schemes that, upon first look seem small, but more often than not, uncover staggering losses.

Product that circumvents the system through theft and diversion flies in the face of states’ efforts to control an unregulated market, and undermines the business goals of small businesses trying to be successful in this space. FOCUS fully supports the use of software to simplify compliance. However, traditional seed-to-sale platforms leave regulatory agencies and cannabis businesses exposed to theft and diversion. New platforms that incorporate standards, and systematize processes, measure the right data to catch and stop diversions schemes. We are finally entering a new era where quality, safety, consistency, and accountability will become the norm for the cannabis industry.

Seed to sale (S2S) tracking systems are a mainstay in the cannabis industry. States and operators alike depend on systems such as Franwell Metrc, BiotrackTHC and MJ Freeway to track compliance and assure cannabis programs run smoothly. Yet many critics are concerned that these systems are inadequate for the needs of cannabis manufacturers/producers and their customers. And in some cases, they are absolutely right to be concerned.

S2S, NOT BULLETPROOF STRATEGY

Here’s the thing – no one likes to be regulated, but it’s necessary to serve the greater good for public health and safety reasons. Without regulations, buying cheese or flying in a plane would be a game of russian roulette where sickness, injury, and in some cases – even death could result. All consumers need basic protections and consumers of cannabis products are no different.

S2S systems work superbly at satisfying adherence to cannabis regulation mandates for companies interfacing with each other. What they don’t do is provide a bullet proof strategy for protecting against internal loss and theft by diversion.

At some point, every cannabis producer will suffer from theft by diversion.

Traceability of product movement is critical in preventing and identifying theft. But the reality is – S2S systems alone can’t prevent an employee from using loop holes to pinch a couple of grams of flower here and there. In fact, most employees who have been in the industry for a while can point out workarounds they’ve identified, or know stories of colleagues who have leveraged weak points in these systems for personal gain.

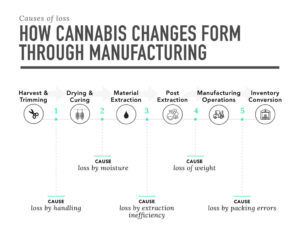

Losing a couple of grams of flower material through theft by employees over the course of a year doesn’t constitute a significant financial loss for the average cannabis company or diversion on a scale that would draw the attention of most regulatory officials. It’s when those the numbers change from a few grams to hundreds or thousands of grams that the impact and risks increase significantly. The easiest places to disguise theft and diversion when relying on current S2S systems are those points where the product changes form.

A TYPICAL DIVERSION SCHEME

Let’s say I decided to take 10g of raw extract from every run for a month. S2S systems that simply record weight and unit quantities assume the honesty of employees in performing these activities. One way I could take advantage of this vulnerability is to attribute the loss to decreased extraction efficiency. Assuming two runs per day, 6 days a week, and $15/gram of concentrate, that means I walk away with $7,200 in material untracked by S2S systems.

From a managers perspective looking at S2S data, it simply looks like the cost of doing business. And the kicker? The manufacturer/producer and regulators are completely unaware that the loss was illicit. What happens if I decide to expand my diversion tactics beyond a month, or worse, share my tactics with others? Let’s look at a year in aggregate:

One thing becomes clear – tracking product movement and weights does not adequately support identification of subtle theft, even if it’s on a grand scale. An organization or regulatory agency hoping to identify diversion at any level – needs to start with a strong foundation for its manufacturing/production program. The first step in creating that foundation involves organizations like FOCUS creating harmonized standards that provide a clear path to establishing procedures that implement, measure, and monitor compliance over time. The next step is collecting the right data.

A NEW WAY TO COLLECT BEHAVIORAL DATA

The best way to combat theft and diversion is to gather the right data and manage standards compliance in simple way. Atlas gXp is a platform focused on addressing key issues that every organization faces when using traditional S2S products. In addition to solid procedures and compliance tracking; collecting behavioral data (such as employee tagging, task completion details, time spent, and location details) – Atlas gives organizational leaders unparalleled visibility into potential theft.

Batch production records provide a unique opportunity for organizations to collect data in diverse environments, with multiple employees performing complex operations – all while avoiding the pitfalls of micromanagement. Not only do these records follow the instructions contained in standard operating procedures but they integrate the collection of behavioral data, seamlessly. Digitizing the data collection process using Atlas gXp allows organizations to streamline everything by linking procedures with standards and associating employee actions with associated data in an immutable way – without the need to review video or piles of paper records.

Here are some examples of common processes used by cannabis manufacturers, and the types of data that should be collected to identify diversion:

Taking a holistic approach to quality management provides organizations a myriad of benefits, most importantly:

- Decreased waste & abuse

- Support for operational consistency

- Increased process efficiency

- Minimized diversion

- Faster, more focused investigations